Great Article on Why Welding Distortion Occurs and How to Minimize It.

Weld Distortion

Lincoln Electric Weld Distortion

To Minimize Distortion

Minimize weld distortion by following this checklist:

-

Less is better – only lay as much weld bead as neccesary.Good fitup is crucial.Use stitch weding (intermittent welds).Alternate welds on either side of the joint.Welding positioners can orientated the weldment to maximize flat-position welding. Flat positioning permits the use of large-diameter electrodes and high-deposition-rate welding procedures.Orintate welds about the neutral axis of the joint.

- Control heat by distributing it as evenly as possible with a planned welding sequence and weldment positioning.

- Weld toward the unrestrained part of the member.

- Use clamps, fixtures, and strongbacks to maintain fitup and alignment.

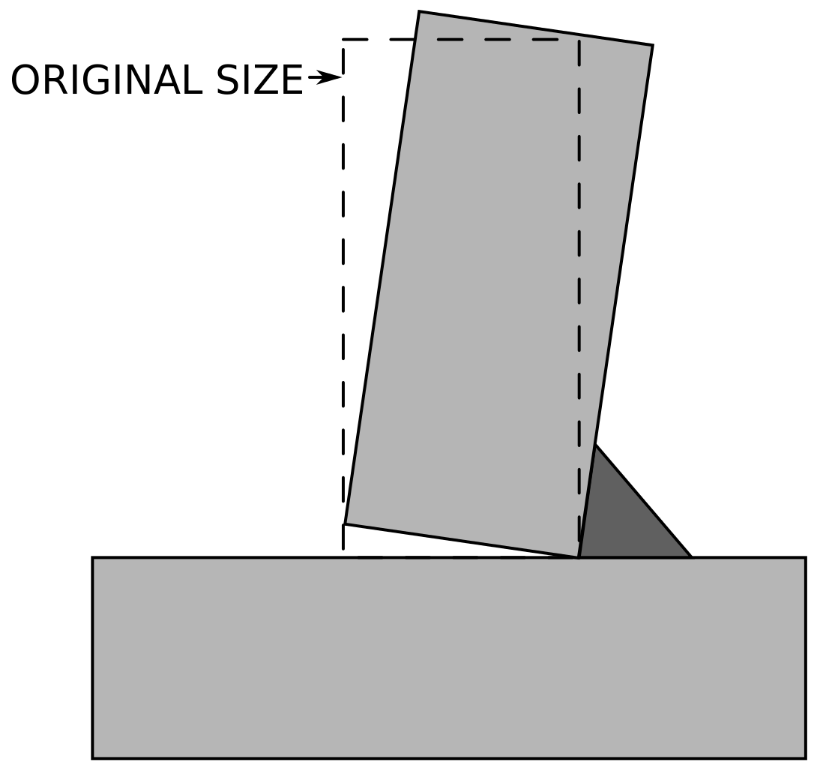

- Pre-bend, pre-stress or preset the members / joints to let shrinkage pull them back into alignment.

-

Continually balance the welds around the neutral axis in the section sequence.

Good fitup is crucial.Use stitch weding (intermittent welds).Alternate welds on either side of the joint.Welding positioners can orientated the weldment to maximize flat-position welding. Flat positioning permits the use of large-diameter electrodes and high-deposition-rate welding procedures.Orintate welds about the neutral axis of the joint.